Bato buckets, which are also known as Dutch buckets and black buckets, are a hydroponic growing system that combines many of the advantages of other systems with relatively few of their disadvantages. They are not very high-tech, but, as we will discuss in this article, their popularity for growing strawberries isn’t without reason.

Jump to:

- What is a Bato Bucket (Dutch Bucket)?

- Setting up a Dutch bucket (Bato bucket) system is simple.

- How is a Bato bucket system different from other hydroponic systems?

- What are the advantages of a Bato bucket system for growing strawberries?

- What are the disadvantages of a Bato bucket system?

- What kind of growing medium do strawberry growers use with Bato buckets?

- What are some cost-saving approaches for setting up Bato buckets?

- Buy your nutrient reservoir with scaling up in mind.

- Some closing helpful hints

What is a Bato Bucket (Dutch Bucket)?

Bato buckets were developed by hydroponics specialists in the Netherlands and first released to the general public in 1989. They are small containers that typically hold three or four strawberry plants. A bucket with three plants is standard. A Bato bucket isn’t a “bucket” in the traditional sense of being a pail with a handle for carrying it. This container is called a bucket because it’s about the size of an average water bucket. Standard Bato buckets for growing strawberries are 11 liters (a little under 3 gallons), but there are Bato buckets with capacities of 10 to 20 liters (a little under 3 to a little over 5 gallons).

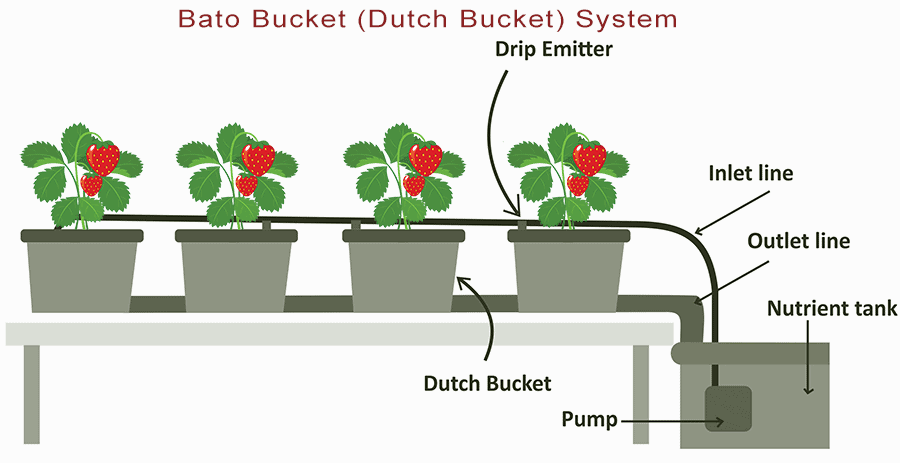

Most commercial Bato bucket systems connect hundreds or even thousands of buckets with irrigation lines and drainage lines. We’ll discuss irrigation and drainage lines in more detail a little later. The only other component of the system is either a nutrient reservoir connected to the irrigation line for smaller setups or an injection system for each bucket in larger, commercial greenhouses. We’ll also discuss these irrigation systems in more detail later in this article.

Supplies and Systems to Use for Your Setup

[amazon box=”B00A1LUFEY,B00CUS5AG4,B086Z3LL53,B07H42BFMG” grid=”2″]

Setting up a Dutch bucket (Bato bucket) system is simple.

Dutch buckets are arranged in a row with their irrigation lines running beside them. The irrigation line is usually PVC of a diameter wide enough to deliver enough irrigation solution for all the buckets. Irrigation line diameters range from ¼ inch to 1 inch (5 to 25 mm), depending on the number of buckets being irrigated. A drain line connects to each bucket and runs back to the nutrient reservoir, both to conserve water and fertilizer and avoid making a slippery mess on the floor of the grow house. The tips of the drip lines are placed below the level of the growing medium at the top of the bucket, one line for each plant, the tip near the plant’s roots.

Bato buckets are not connected by continuous irrigation lines. This would make it impossible to remove a bucket for pest control or replanting. Sometimes Bato buckets are set up in a “run to waste” system that does not return spent nutrient solution to the reservoir, but this is not recommended practice.

Learn how to build a Bato bucket system from the video below:

How is a Bato bucket system different from other hydroponic systems?

Bato buckets are a hybrid of several other hydroponic growing systems for strawberries. Let’s do a quick review:

- Flood and drain. Some indoor strawberry growers plant strawberries in porous pots that placed in a trough. Several times a day the trough is filled with nutrient solution to the brim of the pot and then allowed to drain down and out of the row of pots. The “flood” leaves the perlite, coconut husks (coir), peat moss, or other growing medium around the roots of the plant moist and nutrient-rich, but the growing medium is loose enough that the roots are quickly aerated again after the 10-to-15 minute flood.

- Raft hydroponics. Other growers prefer for their plants to float over a constant bath of nutrient solution. Only the lowest tips of the strawberry’s roots are ever in contact with the water, while the rest of the root mass is kept hydrated by the wicking action of the growing medium. The system has to be drained somewhere between once a day and once a week to keep the nutrient solution fresh.

- Nutrient film technique, also known as NFT. In nutrient film technique, the strawberry plants’ roots are constantly bathed in a nutrient solution that drains out the bottom of the pot, so the roots stay aerated. Some setups include an air line to make sure the roots are constantly surrounded by high-humidity air to keep them from drying out.

It’s also possible to raise strawberries by aquaponics, with plant nutrients coming from a fish tank connected to the system. Commercially viable examples of this approach are not known, however.

What are the advantages of a Bato bucket system for growing strawberries?

Standard Bato buckets are great for growing large plants such as tomatoes and cucumbers. There are smaller, 11-liter buckets made specifically for growing strawberries. While larger Bato buckets usually have to drain into a steel gutter system, Bato buckets are small enough that they can have holes drilled in the bottom spaced to rest on a PVC pipe that carries away drainage to be measured for nutrient depletion and recycled through the irrigation system. These 11-liter buckets have wings that make it easy to raise a row of buckets for easier harvesting.

Bato buckets are scalable. You can work out your growing method with 10 or 100 pots and then plant a thousand or even ten thousand Bato buckets, as many as you have space to plant in your greenhouse. If you need to cut back production, you can take buckets off the irrigation line without harming the rest of your crop. You will need a larger reservoir and some changes in your irrigation injection lines to handle a higher volume of nutrients.

With Bato buckets, growers can deliver precisely measured nutrient solutions for the plants at different stages of development. We’ve discussed how plants need more nitrogen during leaf and stem development and more of certain trace elements during fruiting. The way Bato buckets are connected to their nutrient reservoir, changing the nutrient ratios can be as easy as turning a dial.

Bato buckets make disease control easier. All you have to do to prevent the spread of disease to nearby plants is to disconnect and remove the bucket. Other plants don’t have to be disturbed. And you can change the spacing of your buckets so that diseases and pests don’t spread faster than you can monitor and treat them. You can sterilize the growing medium for reuse once your growing season is over.

One more important advantage of Bato buckets is the ease with which you can swap plants in or out of your growing system. Other methods of hydroponic production such as floating rafts, nutrient film technique, and flood and drain will all risk root damage when you remove plants. Not Bato buckets.

What are the disadvantages of a Bato bucket system?

The biggest problem with Bato buckets is the potential for clogging in the irrigation lines. Even if the lines are only delivering water, they can become blocked by tiny bits of growing medium or outside soil. Nutrient solids that fail to dissolve — a major problem when growers make the mistake of mixing calcium fertilizer with phosphate fertilizer — can block the flow of nutrients altogether. Unlike strawberry plants in other hydroponic growing systems, strawberry plants in Bato pots are completely dependent on their irrigation line connections for both moisture and fertilizer.

Even if the system works 99 percent of the time, the 1 percent of the time it’s clogged can take a bite out of your profit margins. Many growers connect alarm systems to their irrigation lines to alert them when lines are clogged.

Another problem with Bato buckets is that they need to be cleaned between growing seasons. This isn’t a problem unique to Bata buckets. But growers who use Bato buckets will have many more containers to clean than if they used NFT or flood and drain containers. Larger growers will want to find ways to automate this process.

And an obvious disadvantage of planting strawberries in Bato buckets is that the roots of the plant can only grow inside the bucket. When strawberries are planted in a hydroponically irrigated trough, their roots can grow throughout the length and width of the trough. But the ability to deliver nutrients directly to the roots through the tips attached to the irrigation line may make up for this disadvantage.

There’s a problem with Bato buckets that don’t come into play for growers who use the standard, 11-liter buckets for strawberry production. Larger buckets get too heavy for manual labor. If you don’t want to have to use a forklift for moving buckets with soil from place to place in your greenhouse, stick to the 11-liter bucket size.

What kind of growing medium do strawberry growers use with Bato buckets?

The most important attribute of any growing mix strawberry producers use with their Bato buckets is its ability to wick nutrient solution from top to bottom in the bucket. Small particle size is a good indicator of wicking ability. Lava rocks aren’t small enough, while sand is too small. Perlite, vermiculite, and coconut husk work best.

What are some cost-saving approaches for setting up Bato buckets?

The most effective way to save money on a Bato bucket setup for growing strawberries is true for any technology you haven’t used before: Start small! Get to know how Bato buckets work in your greenhouses, in your growing conditions, for your markets, before you bring production to a large scale. Beyond the prudent expansion of your strawberry growing operation, these measures reduce costs and enhance both profitability and the predictability of your revenues:

- Stick to 11-liter buckets. You will save money on the buckets themselves, as well as on growing medium and labor costs. You will also increase revenues by being able to remove pest-infested plants and plants with obvious signs of disease.

- Don’t let nutrient solution run to waste. You need to be testing nutrient solution to make sure that your strawberry plants are absorbing all the nutrients they need. You need to recycle unused nutrients in that solution. And you don’t want to create conditions for slipping and falling. A single worker’s compensation claim can cause your operation financial stress for years.

- Place your Bato plants on the ground or floor rather than hanging them at waist height. You’ll save money on construction materials, but you will do a lot of bending and stooping.

- Learn to mix your own nutrient solutions. Don’t rely on computerized systems to deliver the right nutrients at the right time. But don’t skip on testing equipment. You will always need to know whether your plants are absorbing the nutrients you give them.

There are also a number of potential cost-saving measures that are judgment calls. Here are some of the cost concerns you will need to consider in setting up a Bato bucket growing operation.

- Commercial buckets versus recycled buckets. It’s not hard to find five-gallon buckets, and chances are that they will cost less than the 11-liter buckets designed for strawberries. But you will also have to fill them with more growing medium. They will be harder to move if you need to remove them because of plant disease, and at the end of your growing season. You will have to drill holes for drainage, and, because of size, you may need to place larger buckets in a steel trough instead of resting them on PVC pipe with stabilizing connections on the wings of the bucket. Recycle buckets previously used for other purposes will not have the wings needed to hold them in place in your greenhouse.

- Fitting each Bato buck with a reservoir at the bottom. Giving the roots of your plants a little distance from the bottom of their buckets ensures air flow that will protect the plant from overhydration and root rot. A reservoir in the bottom of the bucket may save plants when the drainage line fails.

- Whether your buckets need to be UV resistant. If you plan to grow your plants in natural light, you can’t grow them in Rubbermaid or other plastics not intended for long-term, heavy-duty use. The plastic from which they are made will become brittle and will break and spill the bucket’s contents to the floor. Or the bucket will leak nutrient solution on the floor.

- Whether your buckets will be clear, white, or some darker, opaque color. Bato buckets for growing strawberries are almost always black. This helps to keep the growing medium warmer during colder months. It also blocks light that would encourage the growth of algae. Algae can stick to the tips of irrigation lines and clog them and interfere with distribution of nutrients to strawberry plant roots. Even if clear or white buckets are less expensive, they are not more cost-effective. All materials that hold plants or nutrient solution should be black to block the growth of algae.

It’s OK to use a variety of materials while you are experimenting with Dutch bucket hydroponic systems. But once you begin to bring your operation to scale, you need to use standard, professionally recommended materials.

Buy your nutrient reservoir with scaling up in mind.

It is amazingly easy to buy, fill, and plant hundreds or thousands of Bato pots. You just need pots, plants, a growing medium, and appropriate plumbing. You may need to buy a larger manifold to make sure that your nutrient solution is evenly distributed to all of your plants. But you should buy your nutrient reservoir with your expansion goals in mind.

If you start off with a larger reservoir, you won’t have to buy a new unit to support larger production. But if you start off with the smallest nutrient reservoir you can find, you will have to buy new equipment to increase production.

Some closing helpful hints

It’s always a good idea, even if you are just starting with one or two Bato buckets, to buy a few commercial-grade 11-liter strawberry buckets so you can get used to their size and feel. When you see how easy they are to fill, to move around in your greenhouse, and to elevate to an appropriate height for easy harvest, chances are that you will be a lot more enthusiastic about using professional-grade Bato bucket equipment, even if it costs a little more.

Manual feeding of your strawberry plants is a lot simpler with fewer startup costs. The problem with manual feeding is that it allows for more errors in mixing and nutrient timing. Automated nutrient systems cost more upfront but help you achieve higher yields with fewer setbacks.

Some Bato buckets are specifically designed for use with coconut coir. The materials in the bucket helps maintain the right pH for nutrient absorption.

Providing a light source beside your plants, not just above your plants, can increase yields by about 15 percent.

There is no rule that says you can only use one kind of hydroponic production. You can have some of your strawberry plants in Bato buckets, some of them in NFT systems, some of them in flood and drain systems, and so on.

Don’t leave maintenance tasks undone at the end of your growing season. It’s tempting to empty and sanitize buckets “later,” but this only invites the reproduction of plant pests and diseases. It’s never a good idea to defer equipment maintenance to the busy beginning of your next growing season.

Bato bucket systems rely on irrigation lines more than any other method of hydroponic production. That is why it is always important to stock spares. You don’t want to have to drive into town and look in half a dozen stores for spare parts to repair your irrigation system. Always have replacement parts for irrigation and drainage lines and their manifolds and injection tips.

Leave a Reply